STEP ONE:

CARBON CAPTURE

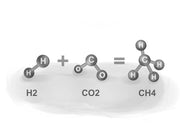

A thermochemical process is used to capture CO2, which is then purified and pumped into high-pressure cylinders for storage.

STEP TWO:

CHEMICAL CONVERSION

Captured CO2 is combined with green hydrogen to produce high-purity Atmospheric Methane™.

STEP THREE:

ROUGH DIAMOND GROWTH

Atmospheric Methane™ is pumped into specialized CVD growing chambers, where the diamond start to take shape, one ambitious atom at a time.

STEP FOUR:

FINAL POLISHING

Once the diamond material has been grown, it is rough cut into small cubes. Advanced software maps the material and produces a cutting plan. From there, the stones are cut and polished using traditional methods.